Explore our comprehensive range of load manipulators, engineered to make load handling safer, easier, and more efficient. RHS Italia designs and manufactures industrial manipulators that support operators in lifting, moving, and positioning heavy or bulky items with minimal effort, promoting true synergy between human and machine.

- Column industrial manipulators

- Sliding ceiling industrial manipulators

- Fixed ceiling industrial manipulators

- Why choose RHS?

Our load manipulators solutions

Column industrial manipulators

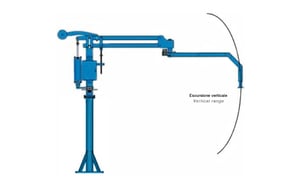

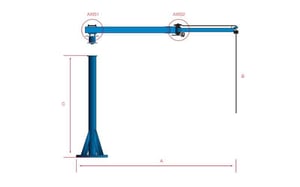

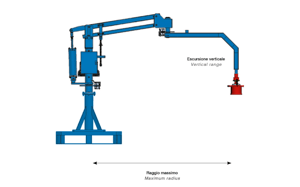

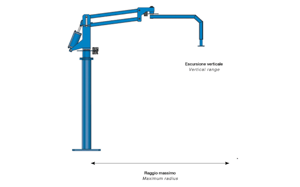

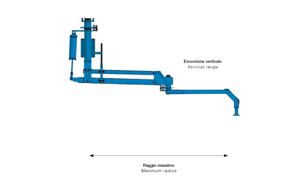

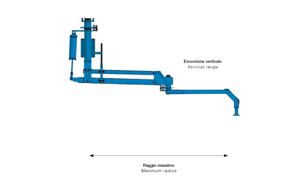

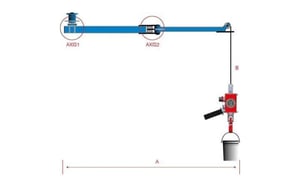

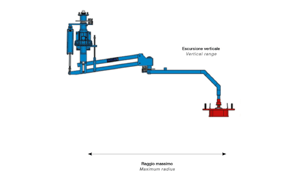

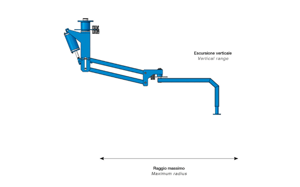

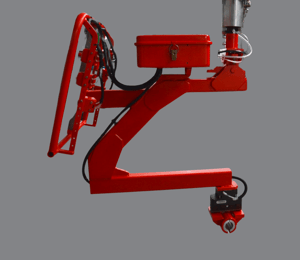

Floor-mounted or self-standing column manipulators are engineered to handle components with an off-center center of gravity, providing stability and precision for heavy or awkward loads at fixed workstations.

Types of column industrial manipulators

Equipped with rigid arms that allow precise handling of off-center loads in a static manner.

discover more

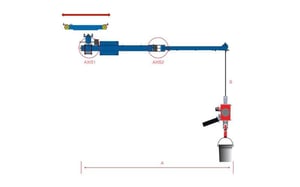

Equipped with two articulated arms, it is ideal for lifting loads ranging from 25 kg to 150 kg.

discover more

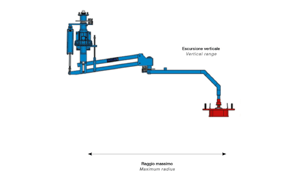

Designed specifically for handling sacks.

discover more

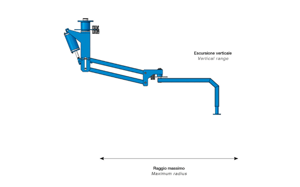

A compact and lightweight model specifically designed for environments with space constraints and for handling light loads.

discover more

Equipped with rigid arms that allow precise handling of off-center loads in a static manner.

discover more

Equipped with two articulated arms, it is ideal for lifting loads ranging from 25 kg to 150 kg.

discover more

Designed specifically for handling sacks.

discover more

A compact and lightweight model specifically designed for environments with space constraints and for handling light loads.

discover more

Equipped with rigid arms that allow precise handling of off-center loads in a static manner.

discover more

Equipped with two articulated arms, it is ideal for lifting loads ranging from 25 kg to 150 kg.

discover more

Designed specifically for handling sacks.

discover more

A compact and lightweight model specifically designed for environments with space constraints and for handling light loads.

discover moreWhy choose RHS load manipulators?

- Maximum safety: our manipulators significantly reduce the risk of workplace injuries, accidents, and material damage. By assisting with heavy or awkward loads, they help companies ensure compliance with safety regulations while protecting both employees and goods.

- Operator-machine synergy: RHS load manipulators are designed to act as the operator’s true partner, enhancing their strength and precision while maintaining full manual control. This collaboration minimizes fatigue and supports natural, intuitive movements.

- Complete customization: RHS delivers solutions that are fully tailored — from load capacity and reach to aesthetic integration — meeting specific operational, technical, and environmental requirements, including demanding ATEX-certified environments.

- Inclusive design: RHS manipulators empower all operators, including those with physical limitations or disabilities. The technology promotes workplace inclusion and ensures everyone can contribute effectively, fostering a more diverse and capable workforce.

- Decades of expertise: with decades of experience serving diverse industries, RHS understands the unique challenges of every sector and applies this know-how to design manipulators that perfectly fit customer needs.

- Enhanced productivity and cost savings: by reducing manual effort and streamlining material handling processes, our solutions increase productivity, lower absenteeism due to injuries, and deliver long-term cost efficiencies.

Gallery

Are you looking for the most effective and innovative solution on the market?

Fill out the form and one of our experts will contact you as soon as possible.