GLASS MANIPULATORS

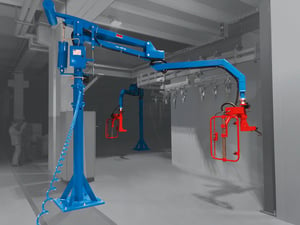

RHS specializes in manufacturing glass manipulators for handling operations, combining advanced technology and ergonomic design.

Ergonomic and safe handling with the RHS glass manipulator

The glass manipulator is engineered to handle delicate components such as panes, windows, façades and glass sheets with maximum gentleness. The system reduces the risk of damage, chipping or breakage, allowing operators to move glass safely across production lines, construction sites and assembly environments.

Thanks to advanced suction technology and intuitive joystick-based control, each glass manipulator guarantees smooth, accurate and fully controllable movements — essential for processes where precision is critical.

.jpg?width=350&height=467&name=IMG_4654-1%20(1).jpg)

Gallery

Why choose a RHS glass manipulator?

Investing in an RHS glass manipulator means equipping your operations with a high-performance, human-centric technology solution. Key advantages include:

- Superior precision and control

The glass manipulator uses high-efficiency vacuum cups and responsive controls to ensure precise positioning, rotation and lifting, even when handling large or irregular glass formats. - Maximum protection of fragile materials

Our glass manipulator maintains a secure grip at every stage, minimizing the risk of surface wear and accidental impacts. - Reduced operator strain

The ergonomic design of each glass manipulator significantly reduces physical effort, supporting the operator’s movements and creating a healthier, safer workspace.

The glass manipulator as an operator’s ally

More than a machine, the glass manipulator is a collaborative tool that enhances human capabilities. Working in synergy with the operator, it reduces fatigue, improves accuracy and lowers the chance of workplace injuries.

Inclusivity is a fundamental value for RHS Italia: thanks to the intuitive and supported movements provided by the glass manipulator, operators with disabilities or physical limitations can participate fully in handling tasks, contributing to efficiency and team integration.

Smart lift glass manipulator solutions

For applications requiring even greater versatility, the smart lift glass manipulator brings enhanced agility and rapid response capabilities.

This advanced variant ensures:

- optimized lifting for vertical and horizontal positioning

- precise control in confined or complex environments

- improved reach and maneuverability for installation operations

The smart lift glass manipulator is ideal for glazing, façade assembly, window installation and all industrial processes where flexibility and compact design are essential.

Tailor-made glass manipulator systems for every industry

RHS Italia specializes in delivering custom glass manipulator configurations designed to integrate seamlessly into existing workflows. Whether for manufacturing, construction, automotive, furniture, architectural components or high-precision assembly lines, we engineer each glass manipulator to meet specific load, orientation and cycle-time requirements.

Our approach reflects the principles of Industry 5.0: technology that supports people, enhances productivity and ensures long-term sustainability.

GRIPPING SYSTEMS

Discover our gripping systems, specifically designed to meet the specific needs of the industrial world. Each tool is designed to ensure maximum efficiency and safety in glass handling, improving workplace productivity and ergonomics.

Can't find your object to move?

Send us a photo and we will contact you to propose your customized solutionOur glass manipulators

We design and manufacture customizable industrial manipulators to enhance efficiency and safety in lifting and handling operations. Additionally, we offer various gripping tools to handle a wide range of loads, from heavy materials to fragile goods.

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover more

Configure your manipulator

Configure the manipulator you want-it's easy, fast, and most importantly, fun.

Assistance

RHS provides timely and reliable support through online, remote, and phone assistance to ensure uninterrupted machine operation and minimize downtime. Our team is available to efficiently resolve any issues and provide expert guidance. Discover more

Industry 4.0 and 5.0

Discover how RHS is leading the evolution towards Industry 5.0, promoting collaboration between humans and machines for a sustainable and efficient industrial future. Discover more