With over 30 years of experience, RHS Italia stands among the leading industrial manipulator manufacturers, designing and producing custom-tailored handling systems that enhance productivity, safety, and ergonomics in every industrial environment.

We combine Italian engineering excellence with a human-centered approach, creating innovative manipulators that perfectly balance technology and usability — the true essence of Industry 5.0.

Table of contents:

- A leading industrial manipulator manufacturer

- Applications and product range

- Custom tailor-made solutions

- Our manipulators

- Comprehensive services

- Sustainability and human technology

- Contact RHS Italia

A leading industrial manipulator manufacturer

As a trusted industrial manipulator manufacturer, RHS Italia combines advanced engineering with human-centered design. Each manipulator is developed in-house, from concept to commissioning, ensuring reliability, performance, and complete customization for every industrial sector.

We serve clients worldwide with a comprehensive range of solutions — from standard lifting devices to fully integrated robotic systems — always designed for maximum efficiency and operator comfort.

Applications and product range

At RHS, we design and manufacture manipulators for diverse applications and loads.

As one of the most innovative manipulator manufacturers, our product range includes:

-

Drum and container manipulators – Safe, ergonomic handling of heavy or hazardous materials

-

Panel and sheet manipulators – Precision alignment and placement with zero effort

-

Wheel and mechanical component manipulators – Reliable lifting for automotive and engineering industries

-

Coil and reel manipulators – Controlled rotation and positioning for delicate or heavy rolls

-

Bag and box manipulators – Fast, intuitive handling for packaging and logistics lines

-

Glass and sanitaryware manipulators – Secure, scratch-free lifting of fragile materials

-

Metal sheet and profile manipulators – Optimized grip and control for steel and aluminum processing

Each manipulator is engineered to guarantee ergonomics, safety, and precision, reducing operator strain and improving process quality.

Explore all the available applications and find the perfect solution for your needs.

RHS designs solutions for coil handling, considering factors such as the core type, material consistency, weight, and rotation requirements.

RHS manipulators are designed for efficient and safe handling of kegs of various sizes and weights. These versatile systems come in different configurations, allowing kegs to be managed both vertically and with a full 360° rotation.

RHS manufactures industrial manipulators specifically designed for handling metal sheets.

RHS specializes in the production of industrial manipulators designed to facilitate the handling of shafts, gears, and a wide range of mechanical components.

RHS specializes in manufacturing industrial manipulators specifically designed for the efficient handling of panels

RHS specializes in manufacturing industrial manipulators designed to optimize wheel handling.

RHS manufactures specialized manipulators for handling sanitary ware, with a strong focus on safety and the delicacy required for handling these products.

RHS manufactures manipulators designed for handling boxes

RHS manufactures manipulators designed for handling bags, offering versatile solutions available with both free and motorized trolleys

RHS specializes in manufacturing manipulators for glass handling, combining advanced technology and ergonomic design

Custom tailor-made solutions

Unlike many manipulator manufacturers, RHS Italia offers a complete Custom Tailor-Made Service.

Every project begins with a detailed analysis of the client’s workflow, space constraints, and production needs.

Our engineering team then designs a fully customized manipulator that integrates seamlessly with existing systems, ensuring total compatibility and optimized performance.

From electric and pneumatic manipulators to advanced robotic handling arms, RHS delivers bespoke solutions built around your process — not the other way around.

Our manipulators

We design and manufacture customizable industrial manipulators to enhance efficiency and safety in lifting and handling operations. Additionally, we offer various gripping tools to handle a wide range of loads, from heavy materials to fragile goods.

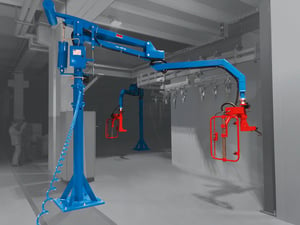

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover moreVideo

Comprehensive services

As a full-service industrial manipulator manufacturer, RHS Italia goes far beyond the supply of handling equipment.

We support our clients throughout the entire lifecycle of their systems — from installation to optimization — ensuring continuous productivity, efficiency, and reliability.

Our comprehensive service ecosystem includes:

Maintenance

RHS provides both regular and extraordinary maintenance services, designed to preserve optimal performance and prevent unplanned downtime.

Through personalized maintenance plans, our technicians perform scheduled inspections and adjustments to keep every manipulator in excellent condition.

In urgent cases, our extraordinary maintenance program ensures rapid on-site interventions — within 24 hours when necessary — restoring full functionality with minimal disruption.

Assistance

Our technical assistance service combines responsiveness and expertise.

RHS offers remote, online, and phone support, enabling real-time troubleshooting and guidance.

When required, our field specialists carry out direct interventions on-site to guarantee continuous operation and peace of mind.

Spare parts

We supply original RHS spare parts, engineered for perfect compatibility and maximum durability.

Each component is carefully crafted and digitally catalogued in our advanced storage system, allowing fast identification and prompt delivery.

This ensures long-lasting performance and minimal machine downtime.

Revamping

Our revamping service offers companies the opportunity to renew and enhance existing manipulators.

By upgrading mechanical and control components, we extend the useful life of machines and improve performance, all with a minimal investment.

It’s an intelligent and sustainable way to align legacy systems with modern production standards.

Process optimization

RHS Italia also provides custom process efficiency consulting, a service dedicated to refining workflows and enhancing productivity.

Through targeted analysis and integration of advanced technologies, we help clients improve operator well-being, reduce waste, and increase overall sustainability.

This holistic approach transforms automation into a strategic advantage for every production environment.

Sustainability and human technology

At RHS Italia, we believe that automation must always serve people.

Our vision aligns with the principles of Industry 5.0, where technological innovation and human creativity coexist in perfect balance.

Every manipulator we design is conceived not only to enhance productivity but also to create safer, healthier, and more sustainable workplaces.

Environmental responsibility

Sustainability begins with design.

RHS develops solutions that reduce energy consumption, limit material waste, and extend the life cycle of each system through durable components and efficient control technologies.

By promoting revamping and reusability, we help our customers minimize environmental impact and move toward a circular production model.

Human-centered innovation

For RHS, technology is meaningful only when it improves people’s lives.

Our manipulators are engineered to reduce physical strain, increase comfort, and enhance operator safety, allowing human skills to remain at the center of the process.

This ergonomic approach transforms automation into a tool for empowerment — enabling operators to work more efficiently, precisely, and comfortably.

Social and industrial sustainability

RHS Italia also embraces a broader concept of sustainability — one that values people, communities, and long-term industrial resilience.

We invest in continuous training, promote a culture of safety and inclusion, and collaborate with clients to design technologies that respect both human and environmental ecosystems.

Through this commitment, RHS stands out among manipulator manufacturers as a reliable partner for a smarter, more ethical, and forward-looking industry.

Contact RHS Italia

Discover how RHS can design the perfect handling solution for your business.

Get in touch with our engineering team today to discuss your project and explore the possibilities of a custom industrial manipulator built for your production needs.

Looking for a custom manipulator that fits your production needs perfectly?

Our design office is ready to develop a tailor-made solution for your company. Fill out the form to contact us!