In a dynamic and challenging industrial environment, handling heavy loads requires a delicate balance between efficiency and safety. This is where RHS pneumatic manipulators stand out as a cutting-edge solution, specifically designed to optimize these critical processes. Discover our product range and learn why they are an essential asset for enhancing workplace safety in your company.

In this page we'll discuss about:

- RHS pneumatic manipulators

- How a pneumatic manipulator works

- Why choose a pneumatic manipulator for your business?

RHS pneumatic manipulators

Our extensive experience in the industry has enabled us to develop a range of pneumatic manipulators that offer an optimal combination of precision and reliability. Thanks to the advanced technologies integrated into our devices, fully aligned with Industry 5.0 goals, our manipulators can handle loads of up to 800 kg with ease and accuracy, ensuring a safe and efficient workflow.

Here’s what we can offer to your business:

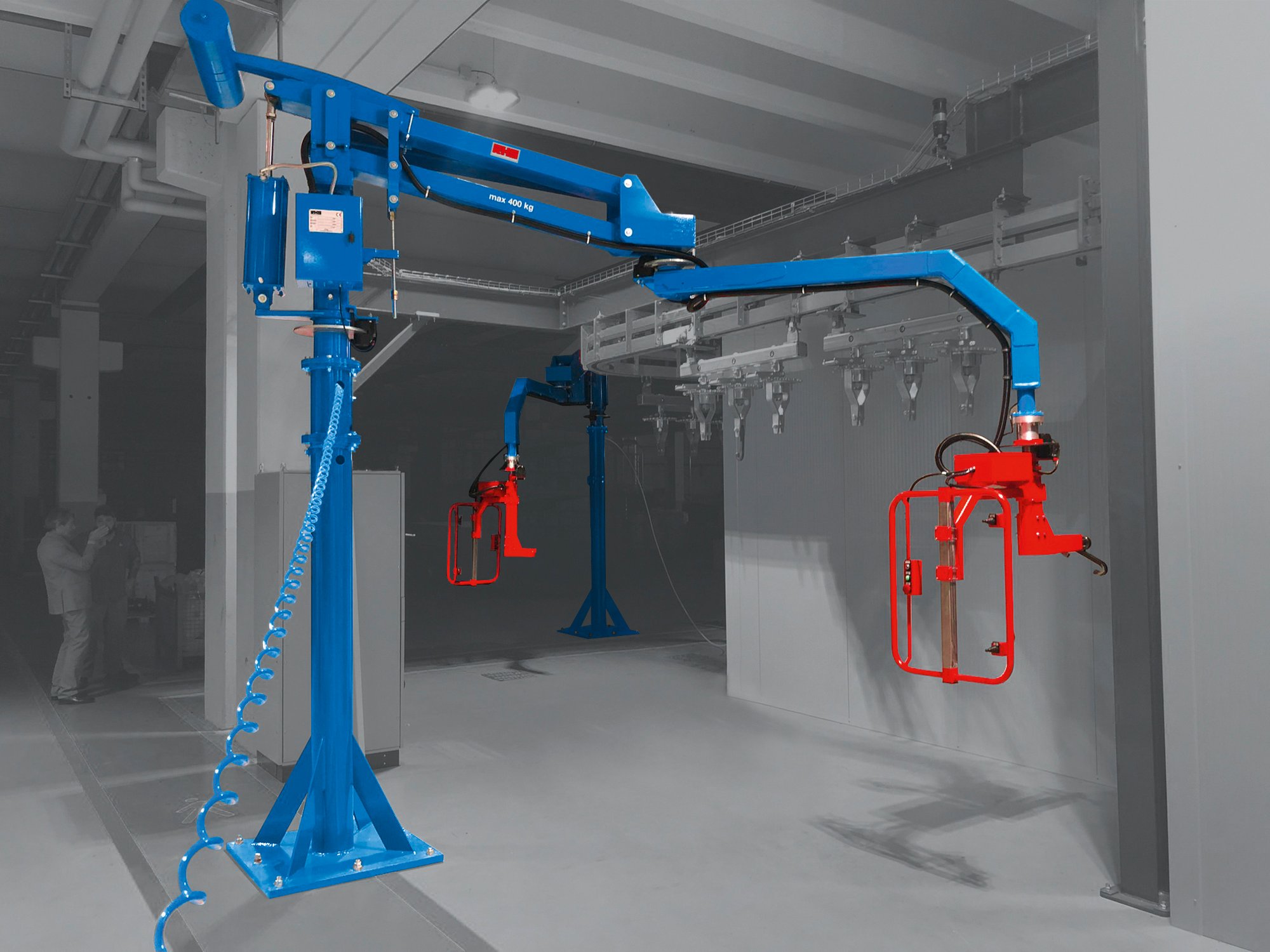

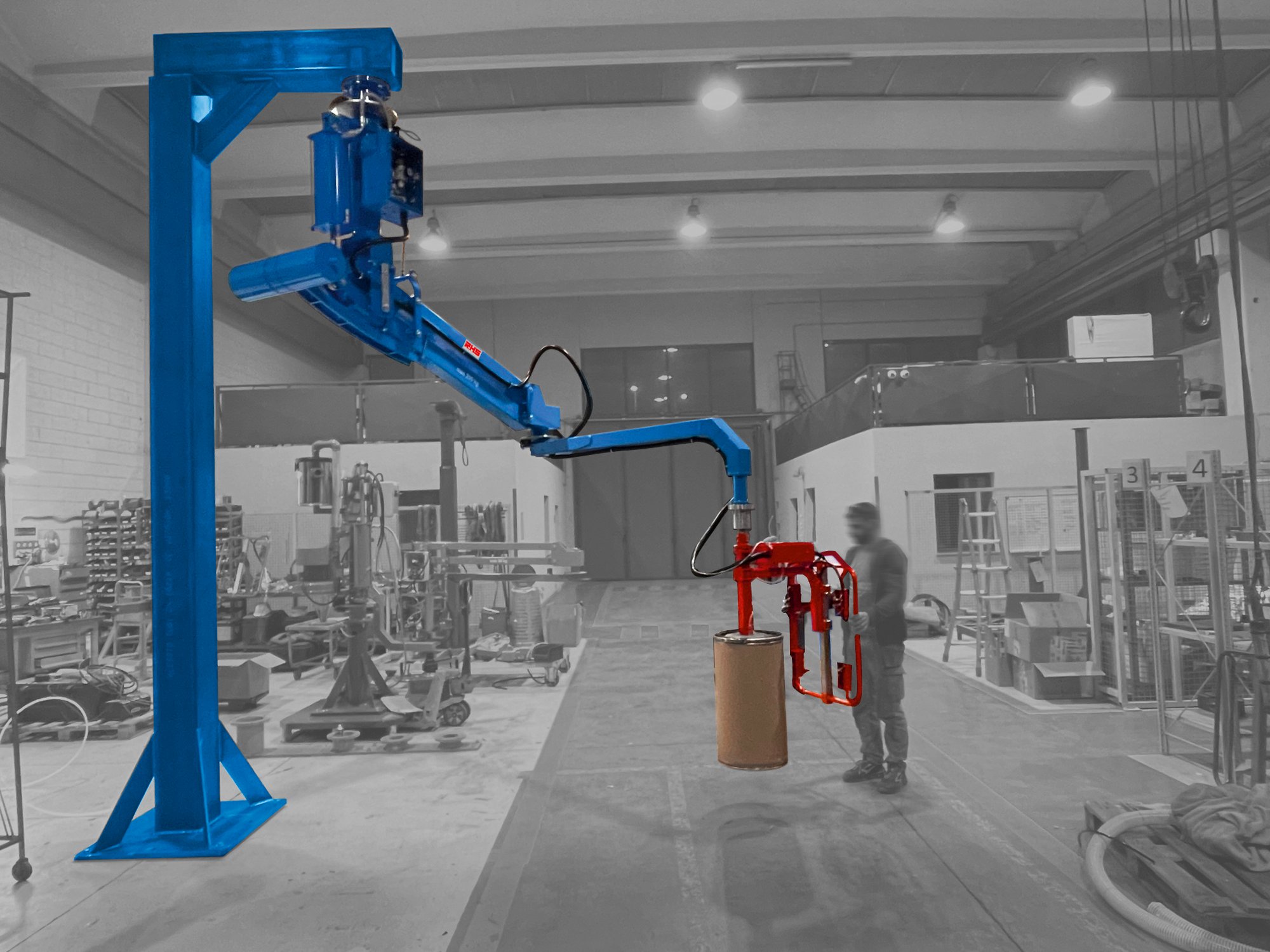

Column manipulator: thanks to its flexibility, ease of use and the ability to be equipped with the appropriate tool, the Bergamo column-mounted pneumatic manipulator is capable of handling a wide range of industrial operations. Mounted on a column and fixed either to the floor or on a self-supporting base, this device enables the safe and efficient handling of components with an unbalanced or offset center of gravity. Additionally, its pneumatic parking brakes ensure safety during operation by keeping the arm static when not moving.

Sliding ceiling manipulator: the rail-mounted translation of this manipulator can be performed either manually or with the help of a pneumatic motor, providing optimal operational flexibility. With the ability to serve multiple workstations using a single machine, our sliding ceiling pneumatic manipulators offer an efficient and practical solution for diverse industrial handling needs.

Fixed ceiling manipulator: thanks to its ability to adapt to various operational needs, this manipulator can handle a wide range of loads with exceptional ease and precision. Equipped with a suspension system, it can be easily installed on existing structures or in standalone positions, allowing the operator to move freely and make full use of the space below without obstruction.

Video

Learn more about RHS manipulators

All three categories of manipulators are available in four additional models, each customizable in an ATEX-certified version:

- Mechanical: this rigid-arm pneumatic manipulator offers various capacities and customization options, featuring advanced safety elements and a continuous supply of compressed air to ensure reliable performance even under critical conditions.

- Rope: made up of two articulated arms, this model uses a pulley mechanism connected to a pneumatic cylinder, converting cylinder energy into vertical cable movement. It provides greater reach and stroke, and it is suitable for lifting loads from 25 kg to 150 kg.

- Bags: this version is equipped with an electric pump, a suction tube, an electric control panel with a thermostat to manage the pump and a balancing system with a vacuum membrane. A storage tank ensures the availability of air even when pneumatic power is not present.

- Micro: designed for fast movements, this model features pneumatic braking mechanisms along with safety devices against dropping and tilting, ensuring safe and ergonomic working conditions. A storage tank guarantees a steady airflow, even during possible pneumatic supply interruptions.

How a pneumatic manipulator works

A pneumatic manipulator operates by harnessing the power of compressed air. At the core of each manipulator there's its pneumatic system which, through cylinders and valves, enables smooth and controlled movement of the mechanical arm.

This technology not only enhances safety by reducing the risk of accidents (a key reason why pneumatic manipulators are frequently used in ATEX environments), but also improves ergonomics for operators by allowing movements that would be otherwise impossible using manual methods.

Why choose a pneumatic manipulator for your business?

Integrating a pneumatic manipulator into your business brings numerous benefits. Among the most important we find:

- Reduced operator fatigue: by automating load handling, pneumatic manipulators help minimize the physical impact on workers, improving their comfort and significantly reducing the risk of injuries associated with manual lifting.

- Increased productivity: thanks to their ability to optimize working time, pneumatic manipulators enhance efficiency and speed in production operations, driving overall productivity growth.

- Minimized risk of workplace injuries: automated load handling significantly lowers the likelihood of accidents, creating a safer work environment that aligns with current safety regulations.

- Versatility and regulatory compliance: pneumatic manipulators can be adapted to a wide range of industrial sectors, ensuring both efficiency and safety while fully complying with industry standards.

Are you looking for safe and efficient pneumatic manipulators?

RHS has the right solution for you.

Are you looking for the most effective and innovative solution on the market?

Fill out the form and one of our experts will contact you as soon as possible.