In today’s fast-paced industrial environment, companies are seeking solutions that improve ergonomics, protect operators, and streamline production. Industrial lift assist systems are designed precisely for this purpose. These intelligent devices support operators during the handling of heavy, bulky, or repetitive loads, reducing physical strain and minimizing the risk of injury while ensuring consistently high process quality.

In this page we'll discuss about:

- What is an industrial lift assist system?

- Why industrial lift assist systems matter

- Our manipulators

- Why choose RHS industrial manipulators

- Discover the RHS approach to industrial lift assist

What is an industrial lift assist system?

An industrial lift assist system is a mechanical or robotic device engineered to support the lifting, positioning, and manipulation of loads in a safe, controlled, and ergonomic manner.

Unlike traditional lifting equipment, lift assist systems work in synergy with the operator, amplifying human capabilities without replacing them. This collaborative approach reflects the principles of Industry 5.0, where human expertise meets advanced technology to create a more efficient and humane workspace.

Industrial lift assists are used across multiple sectors — from manufacturing and logistics to automotive, packaging, and heavy industry. Their flexibility makes them essential in processes where precision and repeatability are as important as strength.

Why industrial lift assist systems matter

In modern production environments, efficiency and human well-being must coexist. Industrial lift assist systems help create this balance by enabling safe, precise, and ergonomic handling of loads. They reduce physical strain, enhance accuracy, and support stable, productive workflows — key elements for companies embracing the human-centered vision of Industry 5.0.

1. Ergonomics & operator well-being

By supporting the weight of the load and assisting movement, lift assist systems significantly reduce physical effort. This lowers the risk of musculoskeletal disorders and operator fatigue, ensuring comfort and long-term sustainability even during repetitive tasks.

2. Precision & control

The assisted, stabilized motion enables smooth and accurate load positioning. Operators can align, rotate, or place components with confidence, improving process quality and reducing the risk of damage to delicate or complex parts.

3. Increased productivity

With reduced physical strain and more efficient handling, workflows become faster and more consistent. Lift assists shorten cycle times, minimize downtime, and allow operators to manage heavier or bulkier loads with ease — resulting in higher overall productivity.

4. Safety at every step

Thanks to controlled movement, secure gripping, and anti-drop features, lift assist systems ensure safe handling in any environment. They help prevent accidents, enhance operator confidence, and strengthen the overall safety culture within the production line.

5. Versatility for multiple applications

Industrial lift assists adapt easily to different loads and production needs. Thanks to modular structures and customizable gripping tools, they can handle bags and sacks, boxes, panels, mechanical components, drums, coils, glass, sanitary ware, wheels, and many other items. This versatility allows companies to streamline workflows and manage diverse handling tasks with a single, efficient solution.

Our manipulators

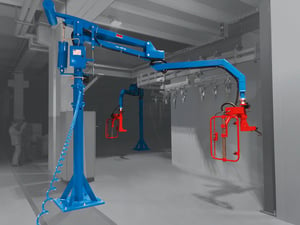

RHS offers tailored solutions for industrial lift assist that improve safety and efficiency in the workplace. Manipulators are among the most effective tools, enabling safe and precise load handling.

We design and manufacture customizable manipulators and provide a variety of gripping tools for loads ranging from heavy materials to fragile goods.

These solutions increase operational efficiency while reducing injury risks and replacing hazardous manual handling.

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover moreLearn more about RHS manipulators

Why choose RHS industrial manipulators as lift assist solutions

With more than 30 years of expertise in robotics and industrial handling, RHS Italia designs and manufactures fully customized lifting and manipulation systems tailored to each client’s workflow.

RHS manipulators embody the evolution of industrial lift assist solutions, combining human-centered engineering with advanced mechanical and pneumatic technologies.

Key advantages of RHS solutions include:

- Tailor-made engineering for unique production requirements

- Ergonomic design that enhances operator comfort and reduces fatigue

- Smooth, intuitive handling through mechanical, pneumatic, or robotic assistance

- High safety standards integrated into every device

- Versatile end-effectors engineered for any load type

- Sustainable, human-centered technology aligned with Industry 5.0 principles

Whether handling panels, bags, coils, boxes, metal sheets, wheels, or mechanical components, RHS provides solutions that elevate safety, efficiency, and process quality along the entire production line.

Discover the RHS approach to industrial lift assist

For companies seeking a reliable partner capable of integrating industrial lift assist systems seamlessly into their operations, RHS Italia provides a complete, end-to-end approach to industrial handling. Our solutions are designed to harmonize with existing workflows, improve ergonomics, and elevate process quality across every production stage.

RHS offers a comprehensive ecosystem of services:

-

custom engineering tailored to specific loads, workspaces, and production cycles

-

installation and on-site technical support to ensure smooth integration and long-term performance

-

maintenance, spare parts, and revamping for maximum reliability and lifecycle optimization

-

process optimization and ergonomic consulting to enhance efficiency and operator well-being

By combining advanced engineering with a human-centered philosophy, RHS empowers companies to create safer, smarter, and more sustainable production environments.

Contact our team to discuss your handling challenges and request a personalized consultation!

Are you looking for safe and efficient industrial lift systems?

RHS Italia delivers tailor-made manipulators that enhance ergonomics, precision, and productivity across every stage of your workflow.

Are you looking for the most effective and innovative solution on the market?

Fill out the form and one of our experts will contact you as soon as possible.