RHS zero gravity lifting arms redefine industrial material handling by combining precision, safety and advanced ergonomics.

Designed to neutralize the weight of the load and enhance operator comfort, these systems embody the Industry 5.0 vision: technology that empowers people and improves the quality of work.

On this page, you can discover:

- What is a zero gravity lifting arm

- The RHS zero gravity range

- Handling capacity & applications

- Why choose a zero gravity lifting arm

- Custom tailor made engineering

- Request your custom zero gravity solution

What is a zero gravity lifting arm?

A zero gravity lifting arm is an articulated, pneumatically balanced system that eliminates the perceived weight of the load.

The operator guides the movement with natural ease while the device maintains perfect balance during gripping, lifting, translating and positioning.

Ideal for repetitive tasks, precise placements and delicate components, zero gravity lifting arms reduce physical strain and elevate workplace safety and productivity.

The RHS zero gravity range

RHS has developed three specialized families of zero gravity lifting arms, each designed around a dedicated balancing architecture and fully customizable with engineered end-effectors. These solutions adapt to the load’s geometry, center of gravity and operating environment, ensuring unmatched control, stability and ergonomic precision in every handling scenario.

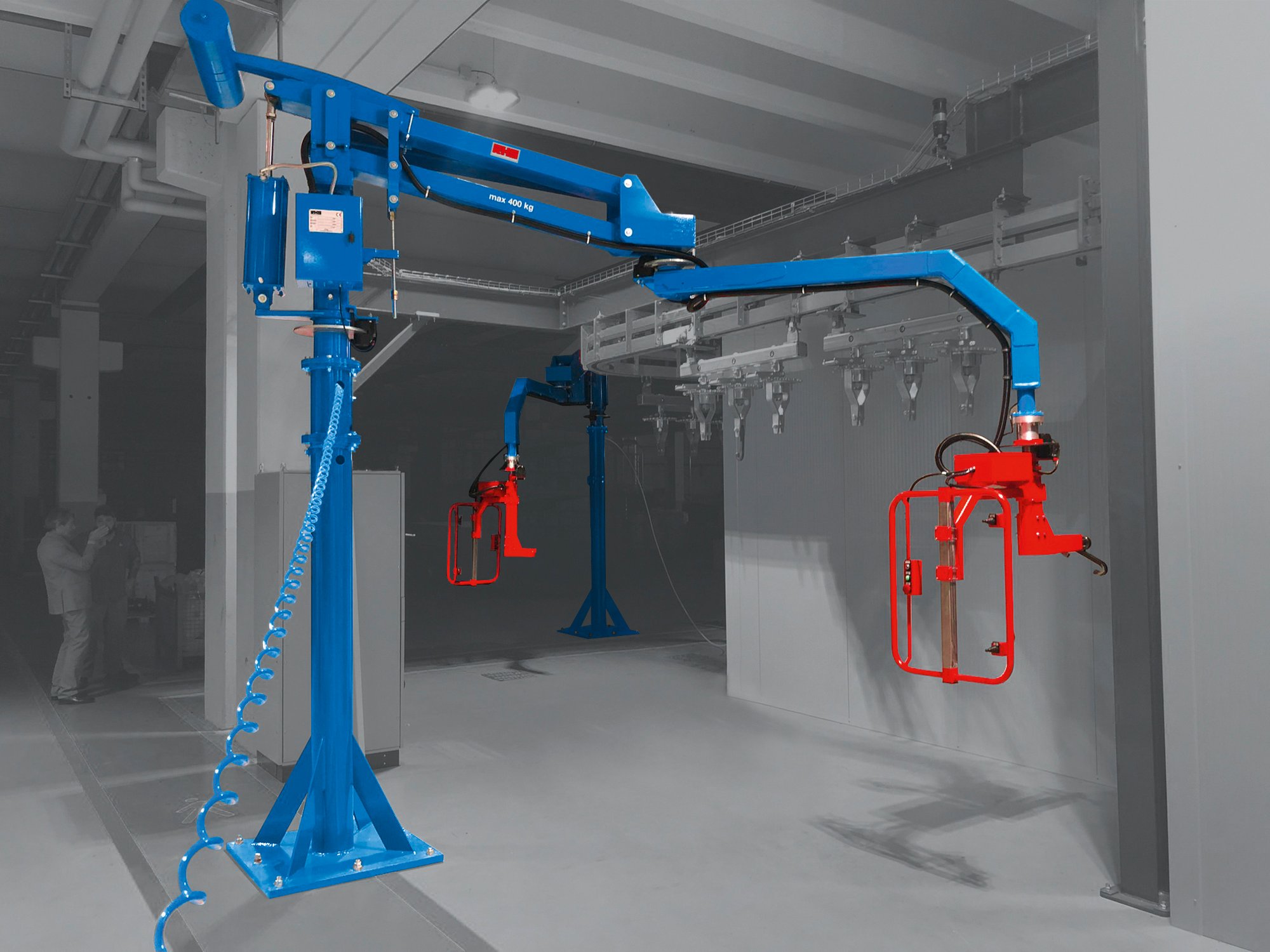

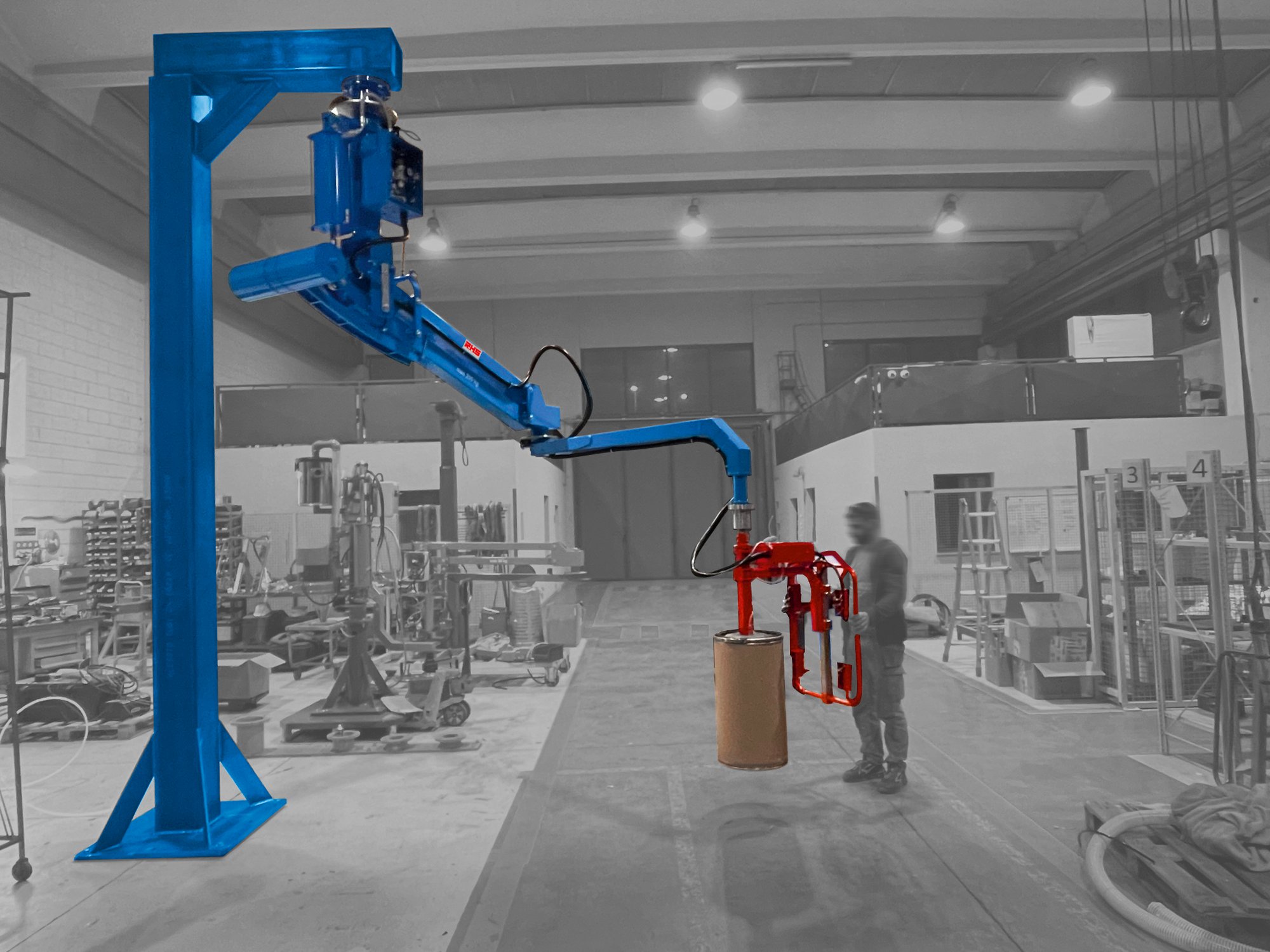

Column manipulators

Engineered for maximum versatility, column-mounted zero gravity arms provide a wide working radius and exceptional stability. Their articulated structure is optimized to manage loads with highly offset or variable centers of gravity, maintaining perfect balance throughout the movement.

Mounted on floor plates or self-supporting bases, they feature pneumatic parking brakes acting directly on the main joints, ensuring safe positioning even during off-axis operations or when handling bulky components.

Fixed ceiling manipulators

Fixed ceiling zero gravity arms free the floor from obstructions and deliver ultra-smooth, low-friction kinematics. The overhead suspension enhances vertical balancing accuracy and allows the braccio to maintain load neutrality even during rapid height adjustments.

These systems can be installed on existing structural frames or dedicated overhead supports, making them ideal for clean, constrained or highly optimized workstations where space and workflow continuity are critical.

Sliding ceiling manipulator

Sliding ceiling zero gravity manipulators extend the concept of effortless handling across multiple stations. Mounted on modular rail systems, they can travel manually with minimal resistance or via pneumatic motorization for longer spans or intensive cycles.

This configuration allows a single arm to serve several work areas, combining perfect load balancing with high mobility—an ideal solution for dynamic production lines, assembly islands and workflows distributed along extended paths.

Video

Find the ideal system for your loads, layout and production needs.

Handling capacity: versatile, safe, designed for every load

RHS zero gravity machines can be equipped with vacuum tools, mechanical grippers, magnets or combined gripping solutions depending on the application.

They safely handle loads of varying shapes, weights, dimensions and fragility, ensuring smooth, controlled operations in every setting.

Typical Applications

- Containers (liquids, powders, drums, pails)

- Panels (sheet metal, composite, insulation, automotive parts)

- Wheels & Coils (rubber, paper, film, complete wheels)

- Mechanical Components (motors, flanges, assemblies, castings)

- Bags (food, chemical, pharmaceutical)

- Boxes (logistics, warehouses, distribution)

- Glass & Sanitary Ware (delicate slabs, sinks, toilets, bathtubs)

The versatility of RHS zero gravity lifting devices makes them indispensable in a wide range of industrial environments, supporting consistent, safe and efficient handling operations.

Why choose a zero gravity lifting arm for your company?

Choosing an RHS zero gravity lifting arm means equipping your production environment with a solution that enhances safety, optimizes workflows and supports the well-being of your operators.

Designed to combine precision, ergonomics and human-centered engineering, these systems deliver tangible benefits across every stage of the handling process.

1. Improved workplace safety

Zero gravity lifting arms reduce physical strain and minimize the risk of musculoskeletal injuries.

By stabilizing the load throughout the movement, they enhance safety even in tight spaces or precision-critical operations—creating a healthier, more protected work environment.

2. Higher operational efficiency

Neutralizing the weight of the load makes lifting, rotating and positioning faster and smoother.

RHS systems reduce cycle times, improve repeatability and support continuous workflows without operator fatigue.

3. Better use of human resources

With heavy or repetitive lifting eliminated, operators can focus on higher-value tasks.

This improves productivity, boosts job satisfaction and helps companies retain skilled personnel.

4. Easy to use and easy to integrate

Ergonomic controls and customizable configurations ensure rapid adoption.

Whether column-mounted or ceiling-based, these systems integrate seamlessly into existing or new production lines with minimal training.

5. Technology aligned with Industry 5.0

RHS solutions enhance the operator’s role and promote more sustainable, human-centered production.

Less fatigue, better well-being and smarter resource usage contribute to a resilient, future-ready work environment.

Request your custom zero gravity solution

Get expert guidance and discover the lifting arm designed specifically for your process.

Custom tailor made engineering

Every RHS zero gravity lifting arm is the result of a meticulous, customer-focused engineering process.

Our solutions are not adapted to your workflow — they are built around it, ensuring maximum ergonomics, safety and efficiency.

-

In-depth workflow and ergonomic analysis

We examine operator movements, workstation constraints, cycle times and safety requirements to design a solution that truly enhances daily operations. -

Comprehensive study of the load and gripping method

Weight, geometry, material, center of gravity, rotation needs and handling frequency are all evaluated to determine the most reliable and user-friendly gripping technology. -

Bespoke design of arm mechanics and end-effector

Each component — from the arm structure to the custom tooling — is engineered to guarantee optimal balance, precision and ease of use. -

Smooth integration into existing layouts

RHS systems are designed to blend seamlessly with current automation, support structures, production flows and safety standards, minimizing installation impact and downtime. -

Full-cycle technical support

We provide installation, operator training, preventive and corrective maintenance, original spare parts and complete revamping services to extend the lifespan and performance of your equipment.

RHS is your single, reliable partner for handling solutions that are smarter, safer and sustainably aligned with the future of industrial production.

Discover the RHS zero gravity range

Work smarter, move safely, elevate productivity.

Contact our specialists for a personalized consultation and find the ideal zero gravity lifting arm for your operations.