Robotic manipulators—mechanical arms designed to replicate and enhance human motion—are essential to modern automation. They deliver precision, safety and efficiency across industries, from manufacturing to harsh environments.

This guide provides a clear overview of how robotic manipulators work, the main types available, and their industrial applications. Discover how RHS Italia develops custom, human-centric handling solutions aligned with the principles of Industry 5.0.

Table of contents:

What is a robotic manipulator?

A robotic manipulator—often referred to as a robotic arm—is an electronically controlled mechanical system designed to execute precise movements across multiple axes.

Its architecture includes rigid links connected by articulated joints, allowing the arm to reach, lift, rotate, and position objects with high accuracy.

Interchangeable end-effectors—such as grippers, suction cups, magnetic tools or cutters—enable the manipulator to adapt to a wide range of tasks and environments.

Robotic manipulators are central in modern industrial automation, ensuring productivity, repeatability, and enhanced safety for human operators.

How robotic manipulators work

A robotic manipulator combines mechanical components, motors, sensors, and control software to generate controlled, coordinated movement with high precision and repeatability. Its operation is the result of several integrated subsystems working together in real time.

Mechanical structure

Links

These are the rigid structural segments that make up the arm. Their length, material composition and geometry define the manipulator’s reach, rigidity and payload capacity. High-performance manipulators often use lightweight alloys or composite materials to optimize strength-to-weight ratio.

Joints

Joints connect the links and enable motion.

- Rotary (revolute) joints allow rotation around a specific axis

- Linear (prismatic) joints provide extension or retraction along a straight line

The arrangement and number of joints determine the manipulator’s Degrees of Freedom (DoF) and overall workspace shape. Precision in joint construction—such as minimising backlash and integrating position sensors—is critical for accurate movement.

Control system

The control system coordinates motor commands, sensor feedback and trajectory generation.

Digital controllers continuously interpret inputs and adjust movement in real time, ensuring smooth and accurate performance even under dynamic load conditions.

Advanced algorithms, including inverse kinematics and motion planning, compute the optimal path to reach a target position and orientation (x, y, z + roll, pitch, yaw).

In more sophisticated systems, force sensors, torque feedback and vision systems can further enhance adaptability, allowing the manipulator to interact safely with varying objects or cooperate with human operators.

End-effector

The end-effector is the functional tool mounted at the tip of the manipulator and determines the nature of the task being executed.

It can take many forms:

- grippers for secure object handling

- vacuum or magnetic systems for smooth surfaces or metallic parts

- cutting or welding tools for fabrication tasks

- precision micro-tools for delicate or medical applications

Interchangeability is a key advantage: by adapting the end-effector, a single robotic manipulator can perform vastly different operations, enhancing flexibility and productivity across industries.

Robot manipulator types

Different manipulator architectures offer unique motion capabilities, workspace geometries and performance characteristics. Understanding these configurations helps identify the most suitable solution for each industrial requirement.

Cartesian / Gantry manipulators

Featuring three prismatic joints that provide pure linear motion, Cartesian systems offer high rigidity and excellent positional accuracy. Their large rectangular or cubic workspace makes them ideal for heavy-duty handling, plastic molding, packaging and palletizing operations where stability and repeatability are essential.

Cylindrical manipulators

Combining linear movement with a rotary base, cylindrical manipulators provide 360° vertical rotation and a compact footprint. They are well suited for loading and unloading tasks, vertical storage environments and production cells with limited lateral space.

SCARA robots

SCARA configurations use a 4-axis structure that remains rigid along the Z axis while delivering extremely fast and precise motion in X/Y. This makes them perfect for high-speed assembly, pick & place operations, electronics manufacturing and tasks requiring short, repeatable cycles.

Polar / Spherical manipulators

These systems use a hybrid arrangement of rotary and linear joints to generate a wide, spherical workspace. Their motion capabilities make them effective in applications requiring curved trajectories or extended reach around obstacles.

Articulated manipulators

With six or more rotational axes, articulated robots offer the greatest flexibility and freedom of movement, closely mimicking the mechanics of the human arm. They are widely used in automotive, welding, metalworking and advanced manufacturing, where complex trajectories and high versatility are required.

Searching for a smarter way to improve handling operations?

RHS Italia provides customized manipulation systems that reduce strain, boost productivity, and optimize every stage of your process.

Custom tailor-made manipulation systems

Custom-made manipulation systems represent an evolution beyond standard robotic arms, as they are engineered to meet the specific operational requirements of each production environment. Instead of relying on predefined configurations, these systems are designed around the real workflow, the characteristics of the load, and the ergonomic needs of the operator.

A tailored manipulator is developed with a focus on:

Operator ergonomics

Custom systems reduce physical strain by adapting motion profiles, gripping solutions and control interfaces to the operator’s natural movements. This leads to safer, smoother and more intuitive handling.

Safety and risk reduction

By aligning the manipulator’s capabilities with process-specific hazards—such as repetitive lifting, awkward postures or hazardous materials—custom solutions significantly lower the risk of injury and ensure compliance with safety standards.

Process efficiency

Tailor-made manipulators optimize cycle times and material flow by matching the exact dimensions, weights and behaviors of the handled items. This results in higher throughput, reduced errors and improved repeatability.

Sustainability and energy efficiency

Designing a system around real operational needs minimizes unnecessary motion, reduces energy consumption and extends the lifecycle of key components. Lightweight structures, efficient actuators and reduced waste contribute to more sustainable production.

Human–machine synergy (Industry 5.0)

Custom manipulation systems are conceived to complement human skills, not replace them. Their design supports collaborative workflows where operators maintain control and oversight, while the manipulator takes on physically demanding or repetitive tasks. This balance reflects the core principles of Industry 5.0—technology enhancing human well-being and creativity.

Applications across industries

Robotic manipulators are used across an exceptionally diverse range of industries, thanks to their precision, repeatability and ability to operate in environments that are unsafe or inefficient for human operators. Their adaptability—enhanced by interchangeable end-effectors and scalable degrees of freedom—makes them a cornerstone technology in both traditional manufacturing and next-generation automation.

- Industrial automation: used for welding, painting, assembly and material handling, improving consistency and throughput

- Automotive & metalworking: perform precision assembly, welding and forming tasks, ensuring accuracy and safety in environments with heavy or complex components

- Plastics & injection molding: extract molded parts, handle inserts and support fast, reliable production cycles

- Logistics & warehousing: enable automated picking, palletizing and depalletizing, reducing manual strain and increasing operational speed

- Healthcare: support robotic surgery and micro-manipulation, where stability and precision are critical

- Harsh environments: operate in radioactive, chemical or high-temperature settings, allowing remote handling where human intervention is unsafe

- Underwater / ROV Systems: assist in inspection, construction and recovery tasks, maintaining precision even in challenging subsea conditions

Discover RHS robotic manipulators

RHS robotic manipulators are engineered to deliver precision, safety and ergonomic excellence across the most demanding industrial environments. Each system is the result of a Custom Tailor Made design philosophy, where every detail—from joint configuration to end-effector technology—is developed around the specific characteristics of the load and the workflow.

RHS robotic manipulators are engineered to deliver precision, safety and ergonomic excellence across the most demanding industrial environments. Each system is the result of a Custom Tailor Made design philosophy, where every detail—from joint configuration to end-effector technology—is developed around the specific characteristics of the load and the workflow.

With decades of expertise in industrial handling, RHS integrates advanced mechatronics, intuitive control interfaces and human-centric design principles to create solutions that enhance productivity while safeguarding operator well-being.

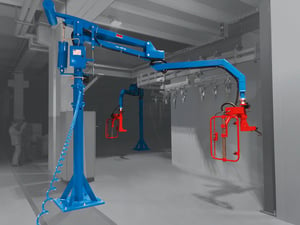

RHS excels in the development of custom overhead and column-mounted manipulation systems, designed to optimize workspace layout and ensure seamless operator interaction. Overhead structures minimize ground obstruction and allow efficient movement even in compact, high-density areas, while column-mounted configurations provide exceptional stability, extended reach and precise load control. Through meticulous structural engineering and bespoke motion design, RHS delivers manipulators that integrate flawlessly into existing environments—offering maximum freedom of movement, ergonomic benefits and long-term operational reliability.

Below, you will find an overview of the main manipulator types, each with distinct characteristics and advantages to support different industrial applications.

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover moreFAQs on robotic manipulators

Below you’ll find answers to some of the most common questions about robotic manipulators. These insights help clarify key concepts, technical considerations and practical aspects to support informed decision-making.

A mechanical arm with articulated joints designed to perform precise, controlled movements in industrial and specialized environments.

It uses motors, sensors and advanced algorithms to coordinate movements along multiple axes through inverse kinematics.

To automate repetitive, dangerous or complex tasks, improving efficiency, quality and safety.

It enhances productivity, reduces human physical strain, and increases process consistency across industries.

Yes. Modern manipulators are designed for seamless integration with existing equipment, conveyors, robots, vision systems and safety devices.

Looking for a custom manipulator that fits your production needs perfectly?

Our design office is ready to develop a tailor-made solution for your company. Fill out the form to contact us!