At RHS Italia, we believe that true industrial innovation begins with human well-being.

Our ergonomic industrial manipulators are designed not only to lift and handle loads, but to create a new balance between efficiency, safety, and comfort.

By combining advanced mechatronic systems with an in-depth understanding of human work dynamics, we turn every movement into a natural extension of the operator’s body.

Table of contents:

- Ergonomics as a design philosophy

- Our manipulators

- Custom tailor made ergonomics

- The essence of ergonomics

- Why choose RHS ergonomic manipulators

Ergonomics as a design philosophy

For RHS Italia, ergonomics is a way of thinking, a design philosophy that places the operator at the heart of every innovation.

Each manipulator is the result of an in-depth study of posture, movement, and interaction, transforming mechanical precision into an intuitive, human experience.

Engineering harmony between man and machine

Every element — from the arm geometry to the grip design — is shaped to ensure natural movement and optimal posture.

By understanding how people truly work, we engineer manipulators that support the human body, not strain it.

This means less fatigue, greater control, and long-term protection for the operator’s health.

Perfect balance

True ergonomics begins with equilibrium.

Each RHS manipulator is perfectly balanced, counteracting the weight of the load through advanced pneumatic or electronic systems.

The operator feels almost no resistance — guiding even heavy objects with a light, precise touch.

This effortless motion translates into greater productivity and total safety.

Intuitive control

A manipulator should move as naturally as the human hand.

RHS control systems respond instantly and smoothly, translating gestures into fluid, predictable movements.

This intuitive behaviour reduces the learning curve and creates a seamless connection between operator and machine — a genuine extension of human intent.

Adaptable interfaces

No two operators are the same.

That’s why we design customisable handles, grips, and control panels, adaptable to the user’s physique, habits, and specific application.

Whether lifting reels, panels, sacks or mechanical parts, each interface is ergonomically tuned to the operator’s comfort and precision needs.

Stable and precise motion

Precision is not just about accuracy — it’s about stability under real working conditions.

RHS manipulators maintain consistent performance, eliminating vibration and drift.

This ensures micro-controlled movements, ideal for delicate or repetitive tasks, while preserving the operator’s ease and safety.

Technology that feels natural

In every RHS ergonomic manipulator, the mechanical structure, control logic, and balance system converge in a single goal:

to make technology invisible, responsive, and human-centred.

The result is an industrial tool that amplifies skill, reduces effort, and transforms handling into a fluid, instinctive gesture.

Our manipulators

We design and manufacture customizable industrial manipulators to enhance efficiency and safety in lifting and handling operations. Additionally, we offer various gripping tools to handle a wide range of loads, from heavy materials to fragile goods.

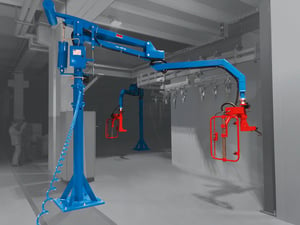

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover moreCustom tailor made ergonomics

At RHS Italia, we know that no two production environments are the same — and neither are the people who work within them.

Every plant, workstation, and operator has its own rhythm, space, and challenges.

That’s why we design custom ergonomic manipulators, engineered to fit the operator as precisely as a bespoke tool.

Designed around your process and your people

Each manipulator is created following a detailed analysis of the working environment, load types, and human interaction patterns.

From layout constraints to operator height and reach, every variable shapes a solution that ensures fluid, comfortable, and safe motion.

This personalised approach transforms ergonomics into a true strategic advantage — enhancing both efficiency and well-being.

Tailored in every dimension

-

Geometry: customised arm lengths, lifting ranges, and pivot points adapt perfectly to each workspace.

-

Control logic: pneumatic, electric, or hybrid balancing systems are configured for optimal responsiveness and precision.

-

Interfaces: grips, handles, and control panels are ergonomically shaped and positioned to suit individual operators or tasks.

-

Load adaptation: whether handling sacks, panels, reels, boxes, or mechanical parts, the manipulator’s dynamics are tuned to the material’s weight and behaviour.

Human centred design

The geometry of each manipulator is shaped around real human movement — ensuring natural posture and effortless control.

Precision balance

Advanced pneumatic or electronic systems maintain perfect balance, letting the operator move heavy loads with minimal effort.

Adaptive handles

Custom grips and control handles adapt to the operator’s size, preference, and the nature of the load — for truly intuitive handling.

Smooth motion dynamics

Fluid, vibration-free motion enhances precision and reduces muscle fatigue during repetitive tasks.

Operator safety & wellbeing

Ergonomic manipulators protect against strain injuries and promote a healthier, safer working environment.

Smart integration

Seamless integration with existing production systems — a balance between automation and human skill.

Why choose RHS ergonomic manipulators

-

30+ years of experience in human-centred design

Expertise and innovation in creating manipulators that align perfectly with human movement, ensuring comfort, safety, and efficiency. -

Certified safety and compliance

All RHS systems comply with European and international standards, guaranteeing maximum reliability and operator protection. -

Reduced strain and improved productivity

Ergonomic balance and intuitive control reduce musculoskeletal effort, speeding up handling operations and improving workflow quality. -

Full lifecycle service

Comprehensive support — from design and installation to maintenance, spare parts, and system revamping — for long-term performance and value. -

Sustainable and durable design

Energy-efficient, low-maintenance, and environmentally responsible solutions designed for a smarter, more sustainable industry.

Discover how RHS ergonomic manipulators can transform your production line — and the way your people work.

Request your custom ergonomic solution today!

Looking for a custom manipulator that fits your production needs perfectly?

Our design office is ready to develop a tailor-made solution for your company. Fill out the form to contact us!