In today’s fast-paced industrial world, handling rolls of flexible material requires a delicate balance between efficiency, precision and operator safety.

This is where a RHS roll manipulator makes the difference: innovative, tailor-made systems designed to simplify roll lifting, rotation and positioning while ensuring the highest standards of ergonomics and productivity.

Discover how RHS technology supports your workflow and why it represents a core asset for any company managing film, paper, textile or plastic rolls.

On this page we'll discuss about:

- RHS roll manipulators

- Tailor-made solutions for efficient handling

- Our gripping tools

- Why choose a roll manipulator

- Engineering excellence by RHS

RHS roll manipulators

With over 30 years of experience in industrial handling, RHS Italia has developed a complete range of custom roll manipulators engineered to ensure safety, reliability and user comfort.

Thanks to advanced mechanical and pneumatic systems, perfectly aligned with Industry 5.0 principles, our manipulators can handle light to medium rolls with controlled motion, minimizing effort and protecting the material surface.

Here’s what we can offer to your business:

Column roll manipulator

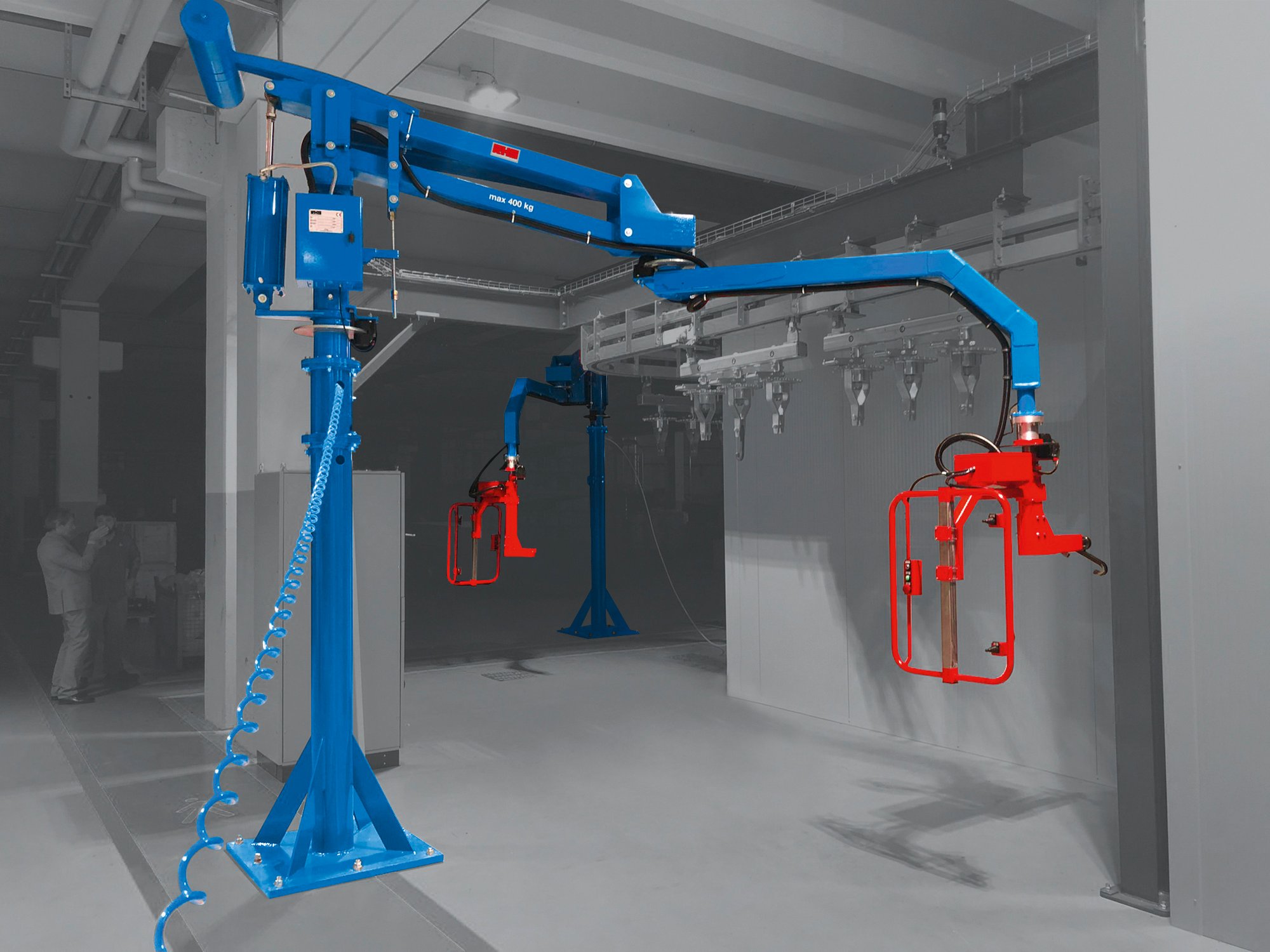

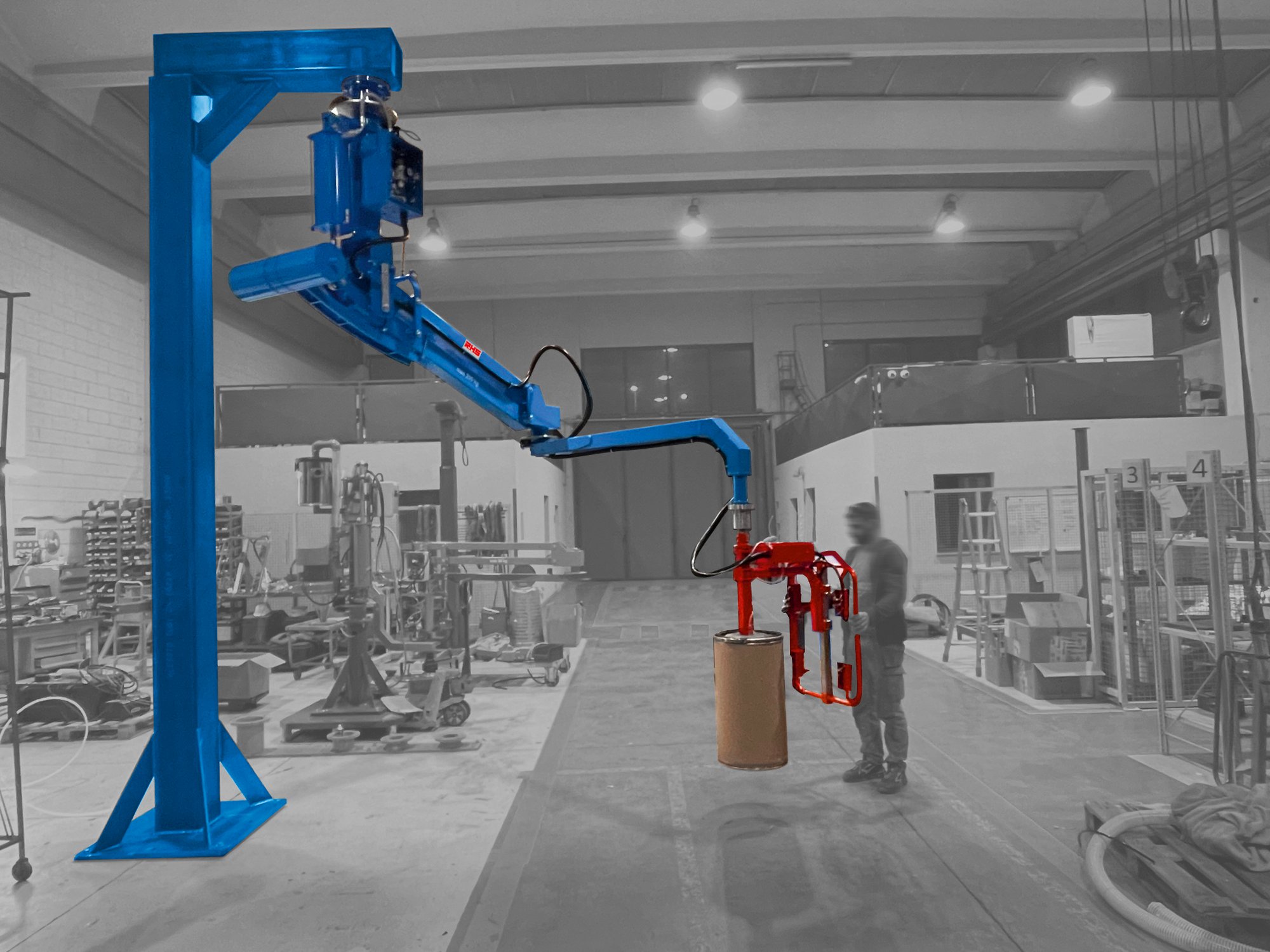

Mounted on a fixed or self-supporting column, the RHS column-mounted roll manipulator offers maximum versatility and ease of use.

It allows safe roll handling even when the load has an unbalanced center of gravity.

Equipped with pneumatic brakes and customized gripping tools (expandable mandrels, clamps or vacuum systems), it guarantees smooth and secure operation.

Sliding ceiling roll manipulator

Designed for wide work areas or multiple workstations, the sliding ceiling roll manipulator can move along a rail system — manually or pneumatically — allowing operators to manage rolls efficiently across different zones.

Its configuration makes it ideal for production lines, converting or packaging departments where space optimization is key.

Fixed ceiling roll manipulator

A suspended solution that frees up floor space and offers full freedom of movement below the working area.

The fixed ceiling-mounted roll manipulator can handle rolls with exceptional precision and stability, ensuring consistent performance and minimal operator strain.

Perfect for integration in clean, organized and ergonomic environments.

Video

Learn more about RHS manipulators

Tailor-made solutions for efficient roll handling

RHS roll manipulators are designed to handle rolls of different sizes, materials and weights with the highest standards of precision, safety and ergonomics.

Each system is custom-engineered to integrate seamlessly into existing production processes, ensuring that every movement — lifting, rotation or positioning — is smooth, controlled and reliable.

At the core of each manipulator lies a mechanical or pneumatic assist system, composed of balancing cylinders, articulated arms and dedicated gripping tools such as expandable mandrels, clamps or suction devices.

This advanced technology enables precise and effortless handling, allowing operators to move rolls safely while maintaining complete control of the load.

By reducing manual effort and improving movement accuracy, RHS roll manipulators enhance operator comfort, process efficiency and material integrity, creating a safer and more productive working environment.

Our gripping tools

Discover our gripping systems, specially designed to meet the specific needs of the industrial world. Each tool is designed to ensure maximum efficiency and safety in handling, improving productivity and workplace ergonomics.

With RHS, you have a range of gripping tools available for manipulators, including rigid arms designed to provide an efficient and secure gripping solution in various applications.

Scopri di più

Among the various gripping tools for manipulators, RHS offers pinch grippers. These tools allow for a robust and efficient grasping and manipulation of objects.

RHS provides a variety of gripping tools for manipulators, including shaped hooks designed to securely hold and lift objects with specific shapes or configurations.

With RHS, you have a wide range of gripping tools for your manipulators, including the simple hook, which allows for load suspension using ropes or chains.

With RHS, you can choose from various gripping tools to adapt your manipulators to specific needs, including magnets designed to provide an effective lifting solution for ferrous materials.

RHS offers a variety of gripping tools for its manipulators, including the mechanical chuck. This device uses a mechanical/pneumatic expanding principle with 120° jaws for gripping.

With RHS, you can rely on various gripping tools for your manipulators, including the mechanical clamp, which allows for the manipulation, suspension, and rotation of objects.

With RHS, we offer a wide selection of gripping tools that can be used with your manipulators, including the roller system designed to facilitate the handling of loads on flat surfaces or conveyors.

RHS offers a wide range of gripping tools to be used with manipulators, including the suction cup, which uses the suction principle to ensure a secure and stable grip on a variety of materials and surfaces.

RHS offers a wide range of gripping tools for its manipulators, including the electric pump suction cup, the most widely used version for over 20 years, highly appreciated for its effectiveness.

With RHS, you have various gripping tools available for manipulators, including the venturi suction cup, an innovative choice as it does not require electrical power or specific pumps.

Why choose a roll manipulator for your business

Integrating an RHS roll manipulator into your workflow brings measurable advantages in terms of productivity, safety and overall process efficiency.

Each system is designed to support operators, optimize movement, and ensure full control during every stage of roll handling.

-

Reduced operator fatigue — by eliminating manual lifting and repetitive strain, manipulators promote healthier working conditions and reduce long-term musculoskeletal stress.

-

Increased productivity — smooth and precise roll changeovers shorten cycle times, keeping production lines running efficiently and consistently.

-

Enhanced safety — controlled, assisted motion minimizes the risk of injuries and prevents damage to delicate roll materials during lifting and rotation.

-

Operational versatility — adaptable to different roll diameters, core sizes and materials, each manipulator can be customized to fit specific industrial layouts.

-

Sustainability and Industry 5.0 alignment — designed around human–machine collaboration, RHS systems combine advanced technology with ergonomics, contributing to safer, more sustainable and people-centered production environments.

Are you looking for safe and efficient roll manipulators?

RHS has the right solution for you.

Engineering excellence by RHS

Every RHS roll manipulator is the outcome of a genuine Custom Tailor Made approach — engineered around your specific production workflow, workspace layout and operator needs.

From the first technical assessment to installation and on-site training, the RHS engineering team collaborates closely with each client to define the ideal configuration in terms of load capacity, reach, balance and control precision.

Each project includes detailed 3D design, ergonomic validation and careful material and component selection, ensuring long-term safety, durability and ease of operation.

This meticulous process allows RHS to deliver advanced roll handling systems that are not only efficient and accurate, but also perfectly aligned with the vision of Industry 5.0 — where technology, sustainability and human well-being work together in harmony.

Are you looking for the most effective and innovative solution on the market?

Fill out the form and one of our experts will contact you as soon as possible.