RHS Italia designs and manufactures custom drum manipulators engineered to lift, rotate, tilt, and position drums of any size, material, or weight with maximum safety and operator comfort.

Whether you handle steel barrels, plastic drums, or stainless steel containers, our manipulators ensure effortless control and total stability — even in demanding industrial environments.

On this page we'll discuss about:

- RHS drum manipulators

- Performance meets ergonomics

- Our gripping tools

- Applications

- Custom engineering by RHS

RHS drum manipulators

RHS Italia designs and manufactures custom drum manipulators engineered to lift, rotate, tilt, and position drums of any size, material, or weight with maximum safety and operator comfort.

Whether you handle steel barrels, plastic drums, or stainless steel containers, our manipulators ensure effortless control and total stability — even in demanding industrial environments.

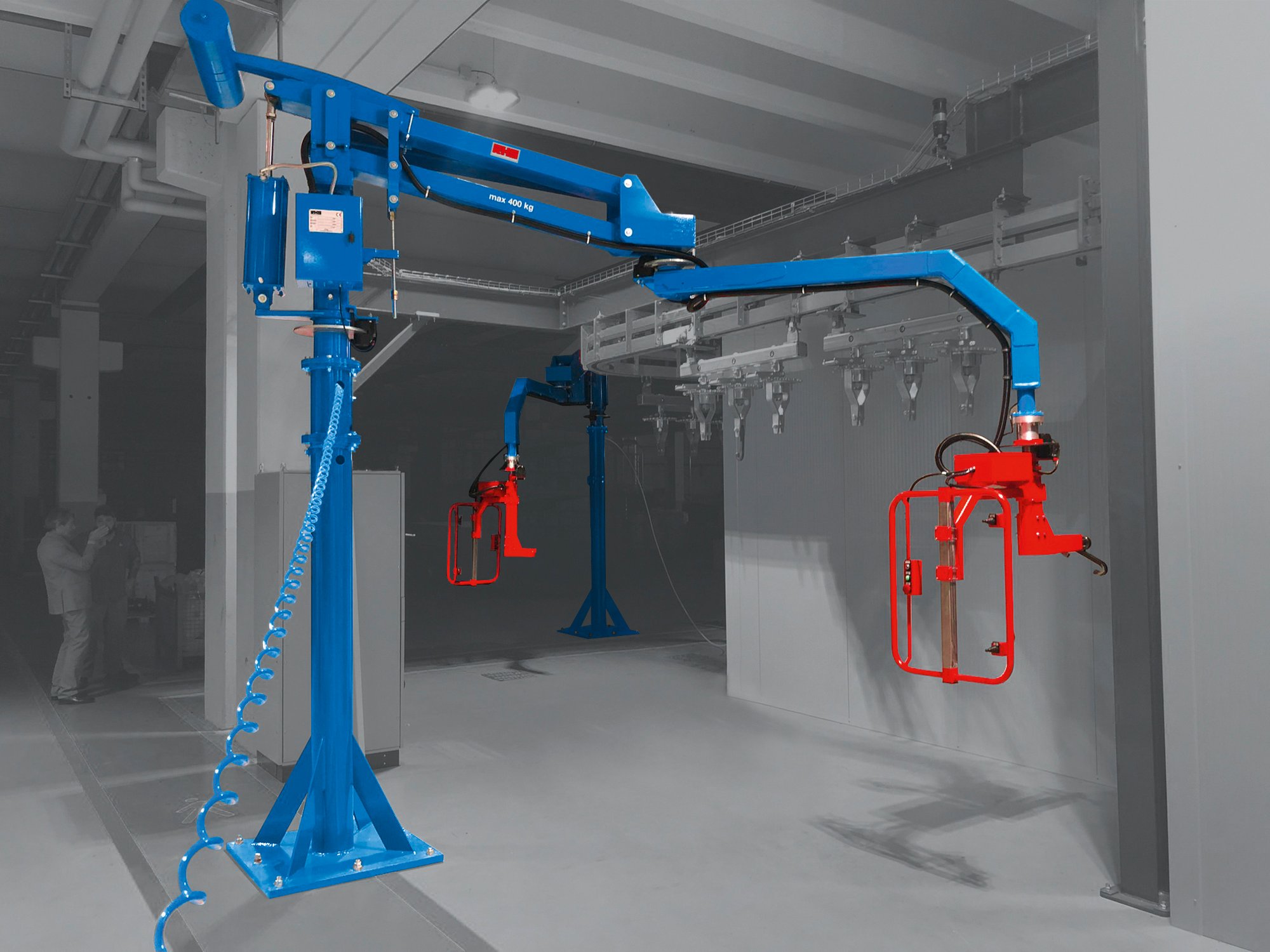

Column drum manipulator

Thanks to its versatility, ergonomic design, and custom tool compatibility, the RHS column-mounted drum manipulator is ideal for lifting, tilting, and rotating drums in a wide range of industrial operations.

Mounted on a robust column — fixed either to the floor or on a self-supporting base — this pneumatic system allows safe and efficient handling of drums with unbalanced or offset centers of gravity.

The manipulator can be equipped with tailor-made gripping tools designed for steel, plastic, or stainless-steel drums, ensuring perfect stability and control during filling, emptying, or transfer operations.

For additional safety, pneumatic parking brakes lock the arm in position when not in use, preventing accidental movements and ensuring secure standby conditions.

Sliding ceiling drum manipulator

The sliding ceiling drum manipulator combines high mobility with exceptional space efficiency.

Its rail-mounted translation system can be operated manually or via pneumatic motor, enabling smooth and effortless movement along a defined working area.

A single manipulator can serve multiple workstations, making it an ideal solution for production lines that require repetitive or distributed drum handling operations.

This configuration reduces downtime and increases productivity while maintaining the same ergonomic balance and precise motion control typical of all RHS systems.

Perfect for industries where floor space optimization and workflow continuity are priorities — such as chemical, food, and pharmaceutical environments.

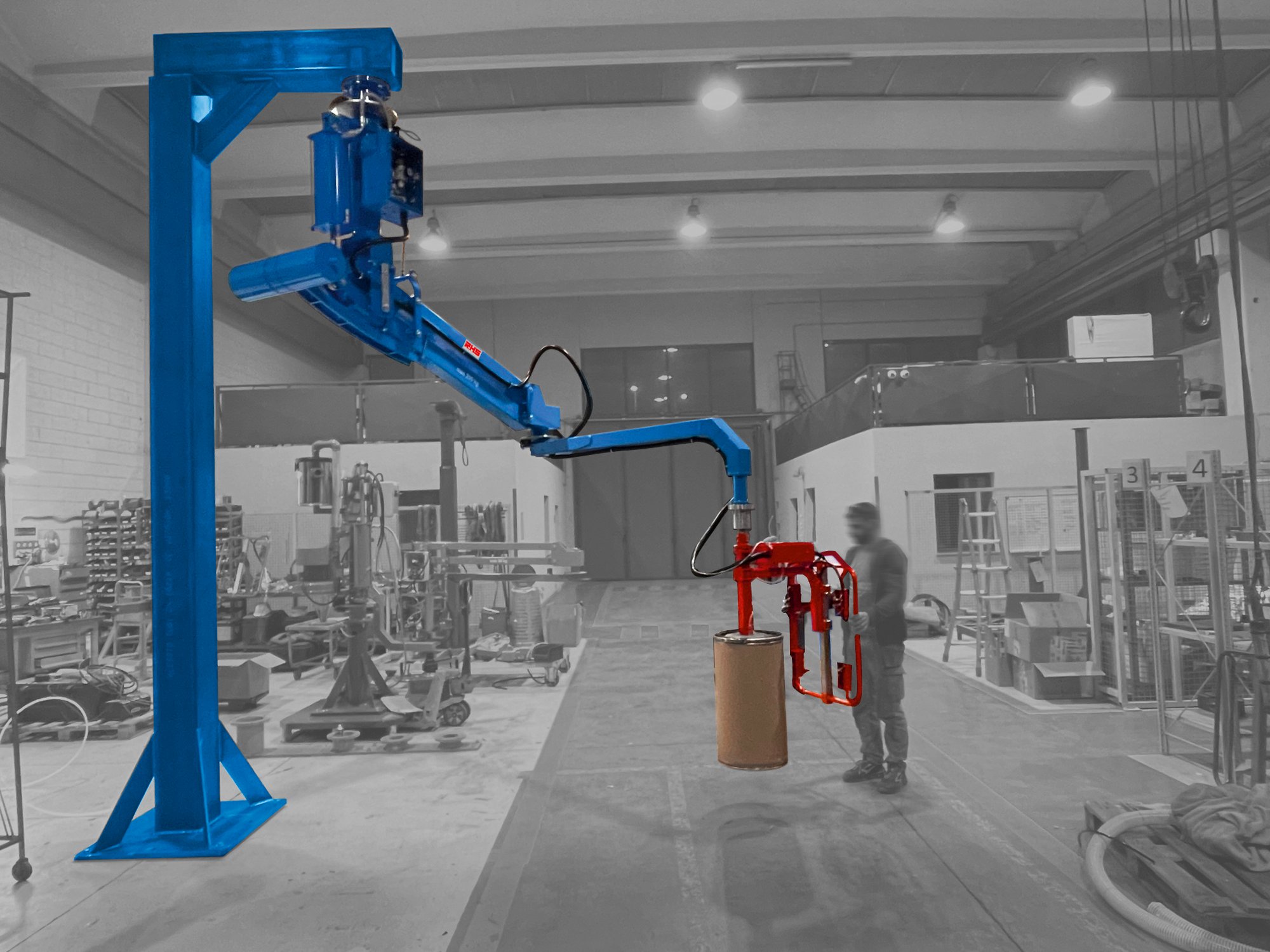

Fixed ceiling drum manipulator

Designed for maximum freedom of movement and operational precision, the fixed ceiling-mounted drum manipulator offers a compact yet powerful solution for drum handling tasks.

Its suspension system allows easy installation on existing structures or dedicated frames, freeing up valuable floor space and providing operators with an unobstructed working area beneath.

This configuration ensures stable, fluid motion during drum lifting, tilting, or rotation, even when handling heavy or offset loads.

The manipulator’s adaptability and high precision make it particularly suitable for filling stations, packaging lines, and other operations where clean, obstacle-free environments are essential.

Video

Learn more about RHS manipulators

Performance meets ergonomics

Each RHS drum manipulator is designed to balance mechanical precision with human-centered ergonomics. Equipped with advanced pneumatic or electric controls and custom gripping tools, it enables smooth, safe, and effortless handling of even the heaviest or irregular drums.

Its intelligent balancing system ensures natural, intuitive movement, enhancing accuracy while reducing operator fatigue and strain. The result is a drum lifting solution that adapts seamlessly to your process — making every operation lighter, faster, and safer.

Main benefits:

- Safe and precise gripping of drums of all dimensions and materials (steel, plastic, or stainless steel)

- Tilting and rotating functions for controlled filling, mixing, or emptying operations

- Pneumatic or electric actuation systems designed for intuitive, responsive handling

- Custom gripping tools adaptable to cylindrical, conical, or ribbed drum shapes

- Smooth integration with existing production lines, conveyors, or mobile handling systems

- Reduced operator strain and improved postural ergonomics, compliant with the highest safety standards

Our gripping tools

Discover our gripping systems, specially designed to meet the specific needs of the industrial world. Each tool is designed to ensure maximum efficiency and safety in handling, improving productivity and workplace ergonomics.

With RHS, you have a range of gripping tools available for manipulators, including rigid arms designed to provide an efficient and secure gripping solution in various applications.

Scopri di più

Among the various gripping tools for manipulators, RHS offers pinch grippers. These tools allow for a robust and efficient grasping and manipulation of objects.

RHS provides a variety of gripping tools for manipulators, including shaped hooks designed to securely hold and lift objects with specific shapes or configurations.

With RHS, you have a wide range of gripping tools for your manipulators, including the simple hook, which allows for load suspension using ropes or chains.

With RHS, you can choose from various gripping tools to adapt your manipulators to specific needs, including magnets designed to provide an effective lifting solution for ferrous materials.

RHS offers a variety of gripping tools for its manipulators, including the mechanical chuck. This device uses a mechanical/pneumatic expanding principle with 120° jaws for gripping.

With RHS, you can rely on various gripping tools for your manipulators, including the mechanical clamp, which allows for the manipulation, suspension, and rotation of objects.

With RHS, we offer a wide selection of gripping tools that can be used with your manipulators, including the roller system designed to facilitate the handling of loads on flat surfaces or conveyors.

RHS offers a wide range of gripping tools to be used with manipulators, including the suction cup, which uses the suction principle to ensure a secure and stable grip on a variety of materials and surfaces.

RHS offers a wide range of gripping tools for its manipulators, including the electric pump suction cup, the most widely used version for over 20 years, highly appreciated for its effectiveness.

With RHS, you have various gripping tools available for manipulators, including the venturi suction cup, an innovative choice as it does not require electrical power or specific pumps.

Applications

RHS drum lifting manipulators are designed for a wide range of industrial applications, offering reliability, flexibility, and process optimization across different sectors.

Chemical and pharmaceutical industries

In environments where safety and purity are critical, RHS drum manipulators ensure the controlled handling of hazardous, sterile, or reactive materials.

Thanks to airtight gripping systems and precise motion control, they minimize contamination risks and guarantee full compliance with GMP and safety regulations.

Custom configurations can include ATEX-certified components, anti-corrosion materials, and cleanroom-compatible finishes for the highest operational reliability.

Food and beverage production

Designed to meet strict hygiene standards, RHS manipulators allow the precise lifting, tilting, and emptying of drums containing ingredients, flavorings, or liquid mixes.

Smooth, stainless-steel surfaces prevent residue buildup, while ergonomic controls help operators work faster and more safely.

This results in optimized material flow, reduced product waste, and consistent quality across every batch.

Paints, lubricants, and liquid materials

For industries dealing with dense, viscous, or sensitive substances, RHS drum lifting systems provide smooth and controlled rotation during transfer or mixing operations.

The manipulator’s stability and precision reduce the risk of spills or product loss, while maintaining a clean and organized workspace.

These features make it an essential tool for applications that demand accuracy, repeatability, and safety in fluid handling.

Waste management and recycling plants

Handling heavy, unbalanced, or sealed drums containing waste, sludge, or recyclables requires robust and reliable equipment.

RHS drum manipulators simplify these operations by reducing manual effort and operator strain, enabling safer lifting and controlled movement in confined or dynamic environments.

Built for durability and easy maintenance, they contribute to safer, more efficient, and sustainable waste-handling processes.

Each application benefits from RHS’s Custom Tailor Made design philosophy — solutions created around your workspace, material flow, and production goals.

Are you looking for safe and efficient drum manipulators?

RHS has the right solution for you.

Custom engineering by RHS

Every RHS drum manipulator is the result of a true Custom Tailor Made approach — designed around your specific production process, workspace layout, and operator requirements.

From the initial analysis to final installation, our engineering team works side by side with clients to define the most effective configuration in terms of load capacity, reach, balance, and control system.

Each project is supported by detailed 3D design, ergonomic validation, and material selection aimed at ensuring maximum safety, durability, and ease of use.

This meticulous approach allows RHS to deliver handling systems that are not only efficient and precise, but also aligned with the principles of Industry 5.0 — where technology, sustainability, and human well-being coexist in perfect synergy.

Are you looking for the most effective and innovative solution on the market?

Fill out the form and one of our experts will contact you as soon as possible.