At RHS, we believe that every company deserves a solution as unique as its production process.

With our custom manipulators, we don’t just build machines — we design smart, ergonomic, and adaptive work companions that connect human intelligence with technological precision.

Discover how we can turn your specific requirements into a tailor-made handling system that enhances efficiency, flexibility, and operator well-being.

- Tailor-made manipulators for every industrial need

- Our custom manipulators

- Our custom gripping tools

- Why choose an RHS custom manipulator

- Applications

- Human meets technology

Tailor-made manipulators for every industrial need

At RHS, every manipulator begins with a simple principle: no two production processes are ever the same.

That’s why we specialize in the design and manufacture of custom manipulators that are not just technically precise, but fully aligned with the way your people and your production system work.

Our engineering team collaborates closely with each client to understand loads, movements, spatial constraints, and operator routines. This detailed analysis allows us to deliver handling systems that perfectly match your operational flow — increasing efficiency while preserving operator comfort and safety.

We go beyond the limits of standard automation.

Each tailor-made manipulator is the result of a multidisciplinary process combining mechanical design, ergonomic research, and human-centric engineering. The result is a machine that fits naturally into its environment — not only performing a task, but improving the quality of the entire workspace.

Whether it’s lifting heavy components, positioning delicate parts, or handling complex geometries, our manipulators ensure:

- precision through advanced balancing and intuitive controls

- safety thanks to certified systems and ergonomic interfaces

- reliability even in demanding industrial conditions

- fluidity of motion for effortless handling

- integration with digital monitoring and Industry 4.0 platforms

Every detail is designed with one goal in mind: to make work simpler, safer, and more human.

Discover our custom manipulators

Discover our range of industrial manipulators, designed and built around your specific production requirements.

Each manipulator is a tailor-made solution, perfectly adapted to your loads, workspace, and operator needs — combining precision, balance, and effortless control.

Thanks to our ergonomic and human-centered approach, RHS manipulators enhance productivity, safety, and comfort, transforming every movement into a natural extension of the operator’s skill.

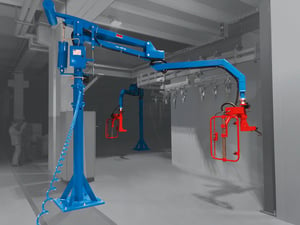

Floor-mounted or self-standing column manipulators allow handling of components with an off-center center of gravity

Discover more

The suspension system of fixed suspended manipulators can adapt to existing structures or be designed for independent positioning.

Discover more

Sliding suspended manipulators operate by translating along rails either manually or with the assistance of a pneumatic motor controlled by the operator.

Discover moreDiscover our custom gripping tools

Discover our gripping tools, engineered to provide safe, precise, and flexible handling for every type of component.

As the key interface between manipulator and product, each tool is designed to match the geometry, material, and sensitivity of your load.

By merging innovative design, advanced materials, and precise control, our gripping tools turn each manipulator into a personalized, high-performance handling system — perfectly aligned with your industrial reality.

With RHS, you have a range of gripping tools available for manipulators, including rigid arms designed to provide an efficient and secure gripping solution in various applications.

Scopri di più

Among the various gripping tools for manipulators, RHS offers pinch grippers. These tools allow for a robust and efficient grasping and manipulation of objects.

RHS provides a variety of gripping tools for manipulators, including shaped hooks designed to securely hold and lift objects with specific shapes or configurations.

With RHS, you have a wide range of gripping tools for your manipulators, including the simple hook, which allows for load suspension using ropes or chains.

With RHS, you can choose from various gripping tools to adapt your manipulators to specific needs, including magnets designed to provide an effective lifting solution for ferrous materials.

RHS offers a variety of gripping tools for its manipulators, including the mechanical chuck. This device uses a mechanical/pneumatic expanding principle with 120° jaws for gripping.

With RHS, you can rely on various gripping tools for your manipulators, including the mechanical clamp, which allows for the manipulation, suspension, and rotation of objects.

With RHS, we offer a wide selection of gripping tools that can be used with your manipulators, including the roller system designed to facilitate the handling of loads on flat surfaces or conveyors.

RHS offers a wide range of gripping tools to be used with manipulators, including the suction cup, which uses the suction principle to ensure a secure and stable grip on a variety of materials and surfaces.

RHS offers a wide range of gripping tools for its manipulators, including the electric pump suction cup, the most widely used version for over 20 years, highly appreciated for its effectiveness.

With RHS, you have various gripping tools available for manipulators, including the venturi suction cup, an innovative choice as it does not require electrical power or specific pumps.

Why choose an RHS custom manipulator

Choosing an RHS custom manipulator means choosing a partner who understands that every industrial challenge requires a unique, intelligent, and human-oriented response.

Each solution we design reflects over thirty years of experience in industrial handling — combining mechanical precision with an unwavering commitment to ergonomics, safety, and efficiency.

Our manipulators are not standard products adapted to your needs — they are tailor-made systems engineered around your processes, materials, and working environment.

1. Fully tailor-made design

Every RHS manipulator begins with a deep analysis of your application: type of load, weight distribution, production rhythm, workspace geometry, and operator interaction.

Based on this data, our design office develops a customized configuration that optimizes both performance and usability.

From pneumatic systems to electronic control units, from arm geometry to grip design, every component is conceived to deliver perfect balance and intuitive handling, even during the most demanding operations.

2. Aesthetic and functional customization

We believe functionality and aesthetics are two sides of the same concept: integration.

RHS allows you to personalize your manipulator with corporate colors, branded graphics, and materials that align with your company’s identity.

Beyond design, we offer a wide range of functional customizations to make the operator’s workspace more comfortable and efficient, such as:

- lockers for personal belongings

- food and beverage holders

- charging and docking stations

- integrated tablets or control screens

- wall-mounted whiteboards and tool supports

Each accessory is designed to enhance daily use, reduce distractions, and create a more organized and pleasant working environment.

3. Operator-centric ergonomics

Ergonomics is not an optional feature — it is the foundation of every RHS custom manipulator.

Through careful balance calibration, smooth movement control, and reduced lifting effort, we help operators maintain natural postures, minimizing fatigue and injury risk.

Our goal is to humanize industrial handling, turning repetitive operations into intuitive, effortless movements.

In doing so, we not only improve safety and productivity, but also quality of life in the workplace.

4. Smart integration with Industry 4.0 and 5.0

All RHS manipulators are ready for the future of manufacturing.

We integrate connectivity systems, monitoring interfaces, and data collection tools that provide insights into usage patterns, maintenance needs, and process efficiency.

But our vision goes beyond digitalization: in the spirit of Industry 5.0, we focus on the synergy between human intuition and robotic intelligence.

Our machines learn from human experience — not to replace it, but to enhance it — creating a balanced ecosystem where technology serves people.

5. Long-term reliability and support

An RHS manipulator is designed to last.

Every project is followed by comprehensive support — from installation and operator training to preventive maintenance and spare parts management.

Our after-sales team ensures that your custom system remains efficient, safe, and precise throughout its entire lifecycle.

Because true customization doesn’t end at delivery: it continues through ongoing care, dialogue, and evolution.

Applications

Thanks to their excellent versatility and customization options, our manipulators are the ideal solution for numerous industrial sectors. Explore all the available applications and find the perfect solution for your needs.

RHS designs solutions for coil handling, considering factors such as the core type, material consistency, weight, and rotation requirements.

RHS manipulators are designed for efficient and safe handling of kegs of various sizes and weights. These versatile systems come in different configurations, allowing kegs to be managed both vertically and with a full 360° rotation.

RHS manufactures industrial manipulators specifically designed for handling metal sheets.

RHS specializes in the production of industrial manipulators designed to facilitate the handling of shafts, gears, and a wide range of mechanical components.

RHS specializes in manufacturing industrial manipulators specifically designed for the efficient handling of panels

RHS specializes in manufacturing industrial manipulators designed to optimize wheel handling.

RHS manufactures specialized manipulators for handling sanitary ware, with a strong focus on safety and the delicacy required for handling these products.

RHS manufactures manipulators designed for handling boxes

RHS manufactures manipulators designed for handling bags, offering versatile solutions available with both free and motorized trolleys

RHS specializes in manufacturing manipulators for glass handling, combining advanced technology and ergonomic design

Human meets technology

At RHS, every custom manipulator is the result of a profound collaboration between engineering and empathy.

We believe that true innovation begins when technology is designed around people — adapting to their movements, rhythms, and needs, rather than forcing them to adapt to the machine.

Through the integration of ergonomic design, intelligent control, and refined mechanics, our manipulators become more than tools: they become trusted work companions that support operators in every action, improving comfort, safety, and efficiency.

This is the heart of our philosophy and the foundation of Industry 5.0 — an era where automation serves humanity, and where productivity and well-being advance together in perfect harmony.

Looking for a custom manipulator that fits your production needs perfectly?

Our design office is ready to develop a tailor-made solution for your company. Fill out the form to contact us!